Balanay JG and Oh J (2021). Adsorption Characteristics of Activated Carbon Fibers in Respirator Cartridges for Toluene. International Journal of Environmental Research and Public Health 18: 8505. doi:10.3390/ijerph18168505

Abstract

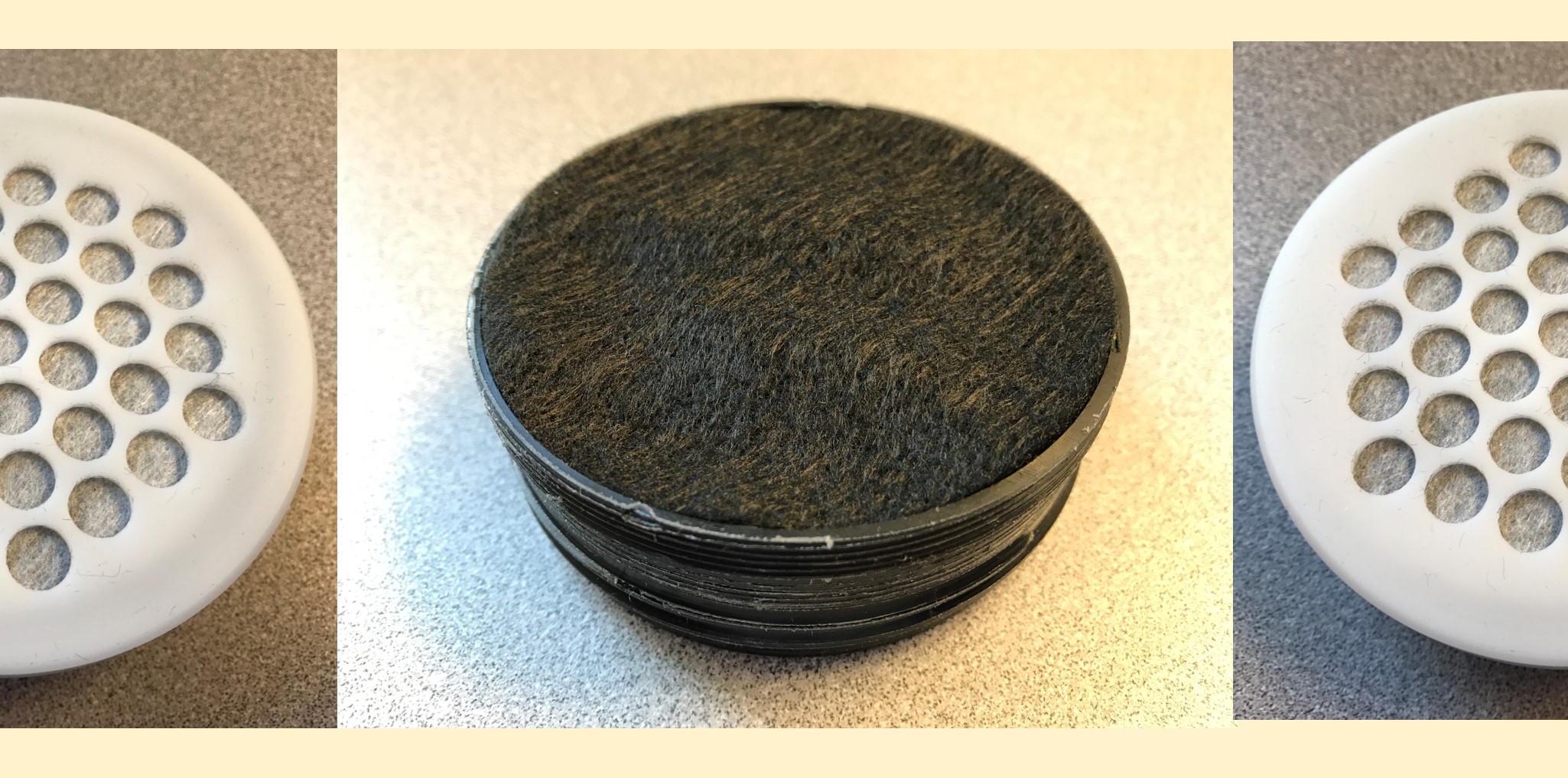

Respirator use has been shown to be associated with overall discomfort. Activated carbon fiber (ACF) has potential as an alternative adsorbent for developing thinner, lightweight, and efficient respirators due to its larger surface area, microporosity, and fabric form. The purpose of this pilot study was to determine the adsorption characteristics of commercially available ACF in respirator cartridges with varying ACF composition for toluene protection. Seven ACF types (one cloth, six felt) with varying properties were tested. Seven ACF cartridge configurations with varying ACF composition were challenged with five toluene concentrations (20–500 ppm) at constant air temperature (23 °C), relative humidity (50%), and air flow (32 LPM). Breakthrough curves were obtained using photoionization detectors. Breakthrough times (10%, 50%, and 5 ppm) and adsorption capacities were compared among ACF cartridge configurations to determine their suitable application in respiratory protection. Results showed that ACF cartridges containing the densest ACF felt types had the longest average breakthrough times (e.g., ~250–270 min to reach 5 ppm breakthrough time) and those containing ACF felt types with the highest specific surface areas had the highest average adsorption capacity (~450–470 mg/g). The ACF cartridges demonstrated breakthrough times of <1 h for 500 ppm toluene and 8–16 h for 20 ppm toluene. The ACF cartridges are more reliable for use at low ambient toluene concentrations but still have potential for use at higher concentrations for short-term protection. ACF felt forms with appropriate properties (density of ~0.07 g/cm3; specific surface area of ~2000 m2/g) have shown promising potential for the development of lighter and thinner respirators for protection against toluene.